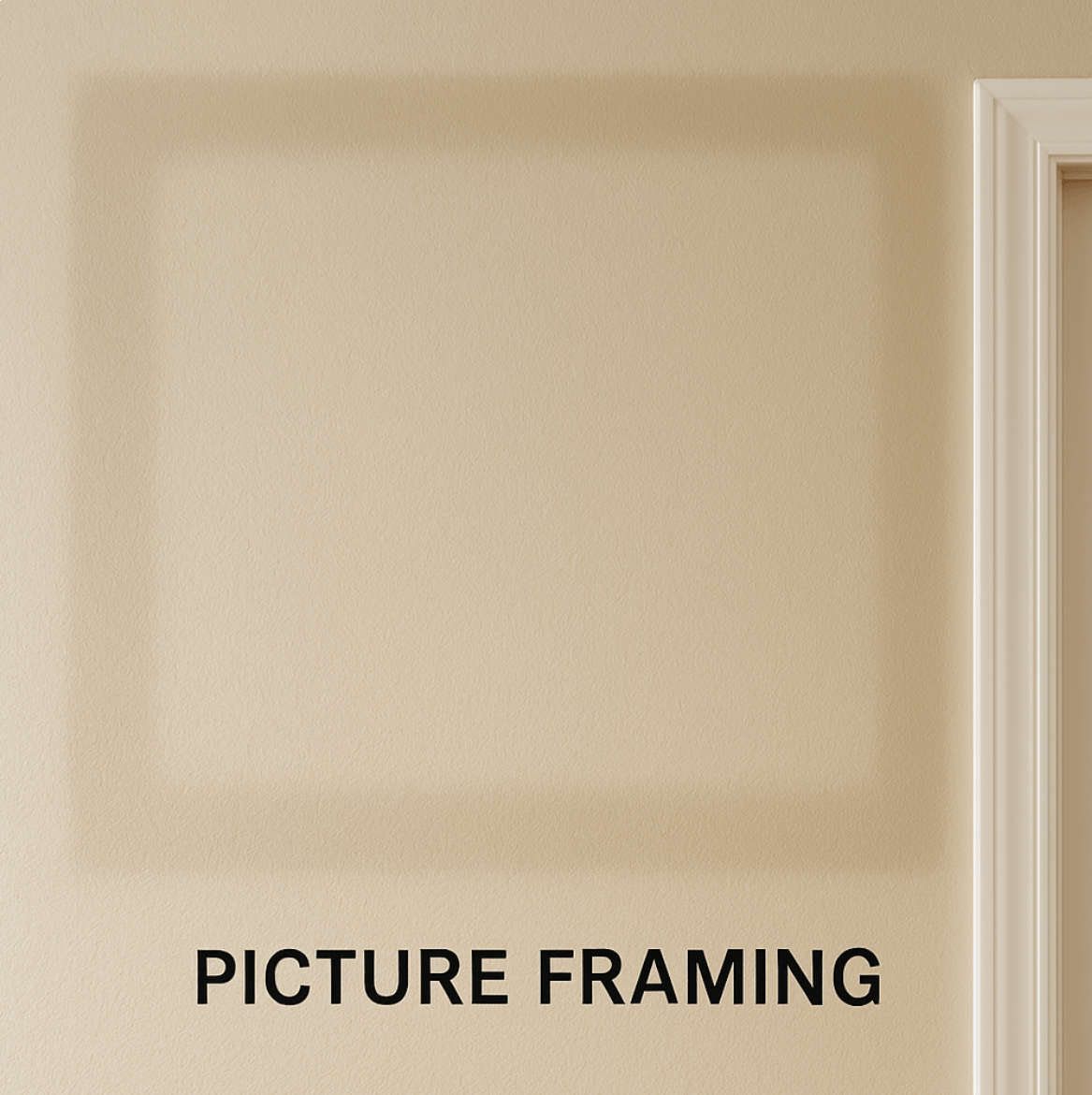

Picture framing is a defect where the edges of a painted area (near walls, ceilings, trim, or cut-in lines) dry with a different colour, sheen, or texture compared to the main rolled surface. The result looks like a subtle “frame” or border around the painted section.

How it Looks

- The edges or borders appear darker, shinier, or duller than the centre.

- Often visible when light hits the wall at an angle.

- Creates a “framed” effect that makes the paint job look uneven.

Causes:

- Uneven application methods – brushing near edges and rolling the main surface leaves different textures.

- Poor blending – not feathering brush or roller strokes into wet paint.

- Paint drying at different rates – edges may dry faster, locking in a different sheen.

- Overloading or underloading brushes/rollers – inconsistent film thickness.

- Using paint with poor hiding power – especially in dark colours or with inadequate coats.

How to fix picture framing

You’ll need

Sugar soap/detergent & water • Microfibre cloths • 240–400 grit sandpaper • Tack cloth • Caulk/filler (as needed) • Undercoat/bonding primer (tint toward topcoat if coverage is an issue) • Quality topcoat (same sheen & brand) • Mixing bucket (for boxing tins) • Brush for cutting-in or mini-roller • 230–270 mm roller with correct nap • Tray/bucket & roller grid • Extension pole • Drop sheets • PPE

Step 1 – Confirm it’s picture framing

- Edges/cut-in areas near ceilings, corners, or trim show different colour or sheen than the rolled centre.

- Check for low hiding (dark colour underneath), brush texture ridges, or thin/over-thick edge films.

Step 2 – Clean the surface

- Wash walls with sugar soap, rinse, dry. Removes residues that can affect sheen.

Step 3 –De-nib and de-gloss the borders

- Lightly sand the framed edges to knock down brush texture and level ridges.

- Feather 100–150 mm into the field; dust off with a tack cloth.

Step 4 – Prime to equalise (as needed)

- If coverage was the issue or the wall is patchy/porous, spot-prime the edges.

- For strong colours/high contrast or lots of patching, prime the whole wall with an undercoat/bonding primer (tinted toward the finish colour) to make porosity and sheen uniform.

Step 5 – Mix & set up correctly

- Box all paint tins into a single bucket for colour/sheens consistency. Stir thoroughly.

- Choose the right roller nap for the substrate; load evenly (don’t dry-roll).

Step 6 – Recoat with “cut-in & roll-in wet” technique

- Work one wall at a time.

- Cut in only a manageable length (≈1–2 m).

- Immediately roll that section, overlapping the cut-in by 50–100 mm so the roller blends the edge while both are wet.

- Maintain a wet edge across the wall. Finish each section with light, one-direction lay-off strokes (top-to-bottom).

Step 7 – Apply full, even film build

- Follow the spread rate; avoid over-brushing edges or over-loading corners.

- Roll as close as possible to trims/corners so the roller texture matches the field.

Step 8 – Second coat

- After full dry/recoat time, repeat Step 6 for a uniform finish.

Step 9 – Inspect under raking light

- Check edges from multiple angles. Lightly nib-sand and touch up if required (re-prime any burn-throughs).

Prevention checklist

- Use the same brand, sheen, and batch; always box tins.

- Keep application methods consistent; consider a mini-roller for cutting in to match roller texture.

- Control film thickness—don’t leave heavy brush bands at edges.

- Work in sensible conditions (10–30 °C, RH < 85%); use a conditioner/retarder only if the manufacturer allows to extend open time in hot/dry rooms.

- For deep/bright colours, plan 2–3 coats or use a grey-tinted undercoat for hiding.

- Good lighting during application reduces missed bands.

Call a pro when…

- Severe sheen/colour mismatch persists after full-wall recoats, or specialty finishes (high-gloss, metallic, textured) are involved.